Our cars and trucks have all different kinds of wheels. The wheels on personal cars are often a fashion statement. If it's not the owner's style, it's the car designer's style.

Commercial truck wheels are all about function. Sure, you might see some polished aluminum wheels with spike shaped lugnuts, but most truck wheels are all about practicality.

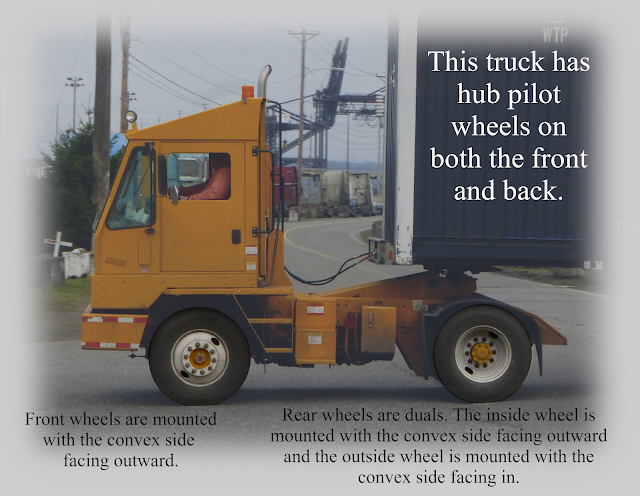

The first thing you've probably noticed is that the front wheels look different from the rear wheels. That difference isn't so much the wheels themselves, but the way they are mounted. All of the wheels that are mounted next to the truck frame have the convex side mounted outward. This allows room for brake hardware on the inboard side. In the rear of the truck, a second tire is mounted on the same axle, this time, with the concave side facing out. This allows for shorter studs (bolts), a stronger arrangement.

A second visible difference has roots in technology, tradition, and thievery.

Most modern trucks have

pilot style wheels. They look much like a basic car wheel with some holes around the edges and some bolts near the center. They are removed in one piece with the tire attached to the wheel.

Dayton or "s

poke" style wheels are the older style. With this style, the tire and the outer rim are removed while the center star-shaped portion stays attached to the axle. The primary advantages of this style is that they are lighter weight and they require lower torque to install and remove. Roadside tire changes are much easier.

The other advantage to Dayton wheels is that they are incompatible with pilot wheels. That's why you see them on intermodal container chassis. A dishonest truck owner can't easily steal new tires from the trailer and install them on their truck.

Dayton wheels were more popular longer on East Coast than they were out west.

The third difference we sill learn about is more difficult to see.

There are two types of pilot wheels:

Stud pilot or Budd (the earlier technology) and

Hub pilot. Stud pilot wheels are lined up (piloted) on the wheel studs (you might think of them as bolts). The lug nuts have a cone shape where they contact the wheel. Hub pilot wheels, the new and more common style, have washers under the lugnuts. The washers make the lugnuts appear a little larger in diameter.

In another post, I will address steel vs. aluminum, super singles, and rotational weight. Did I miss anything? Please let me know in the comments below.